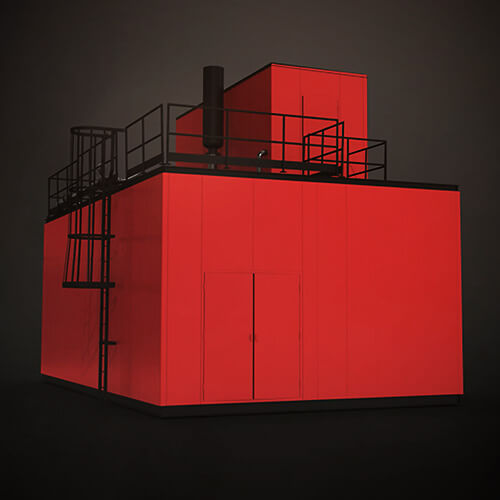

BOILER ROOMS

THE ONE-STOP ALTERNATIVE TO COST-EFFICIENT FABRICATION

“The bottom line: When you team up with Simoneau, you’re dealing with boiler makers at heart who are passionate about making the most optimal and budget-conscious boiler solution that taps directly into your success. Learn how design-built solutions can save you time, money and operational headaches.”

Choose an energy partner that delivers a fully functional end product

Coming up with a design-build solution involves optimizing a boiler room’s efficiency by taking on the entire design process and layout. As an all-encompassing design builder with extensive proficiency in boiler room efficiency and strong boiler industry knowledge, Simoneau brings a level of expertise that perfectly complements any third-party engineer or external source. It allows you in turn to get the most optimal and economical end product.

Value engineering that gives you an edge

Boiler engineering is a trade of its own. To ensure a successful delivery, you must rely on a team of knowledgeable engineers who are boiler makers at heart and are trained to provide you with innovative designs that fit your energy needs as well as your installations’ unique configuration.

- Trust them in defining detailed specifications

- Ask them for a few design alternatives and choose the most cost-efficient one

- Let them calculate your energy performance ROI

- Give them the challenge of solving a footprint situation or pushing the limits of steam or heat production

- Trust them with your documentation needs

Benefit from an integrated approach to boiler fabrication

Your next boiler replacement project deserves the best in the trade. Partner up with a well-rounded team of experts who are used to working together and delivering a flawless end product.

- Project management

- Boiler making

- Equipment sourcing

- Combustion

- Electrical

- Plumbing

- Construction

Simoneau’s multidisciplinary inhouse skills, which include, engineering, manufacturing, installation and equipment servicing, are not only its best assets in terms of boiler design and concept, but also a great cost-effective alternative to outsourcing.

In the end, dealing with Simoneau means you don’t have to compromise when acquiring a new boiler, due in part to its high longevity.

Mobile boiler rooms

Prefabricated boiler solutions

Containerized solutions

District heating solutions

Heat recovery solutions

Life cycle issues (outdated boilers beyond repair)

New design for processing/power plants

Ancillary equipment replacements

Limited boiler room space allocation

Batch processing and varying power production

Plug-and-play approach to energy solutions

Long-term energy savings

Payback (investment)

Minimized environmental impact

Aligning value engineering with boiler performance needs/options

Comparative model approach on capacities and redundancies

Fabrication and testing in a controlled environment

Limited onsite presence