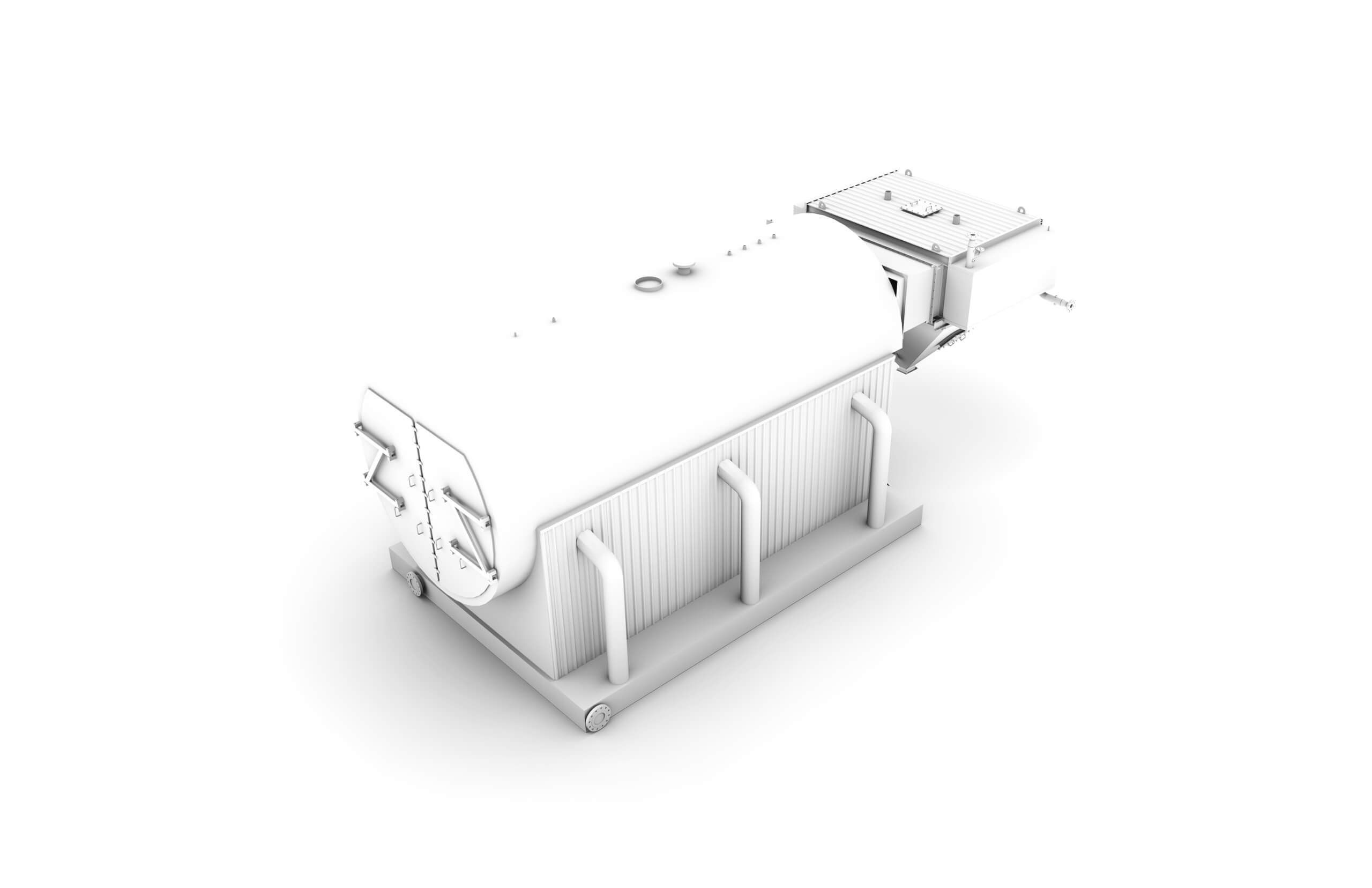

HYBRID BIOMASS FUEL BOILER

Part fire part water steam generator

The Hybrid Biomass Fuel Boiler integrates a full waterwall furnace with a steam generating firetube section. It maximises heat transfer through the extensive radiant and convective surface combining watertube and firetube steam generation.

Hybrid boilers are best utilized when a bi-product is readily available as an alternate fuel (wood, manure, biomass, bagasse, etc.). Turn inconvenient wastes into true power efficiency.

- Cost savings from alternative solid fuel firing

- Tax incentives

- Wetback firetube steam generating section

- Open-bottom furnace fitting a variety of combustion systems

- Reliable source of high-quality, dry saturated steam (up to 99,5%)

- Extensive capacity range and excellent long-term reliability

- Specially designed for commercial, industrial and institutional applications

Advantages

Specifications

Low or High Pressure Steam Boiler

Solid Residue Burning

Full Waterwall Furnace

Large Downcomers Pipes

Optional Economizer

15 to 450 psig

5,000 to 50,000 PPH

ASME Code Construction

Registered at the National Board (NB)

Combustion

BURNERS

Large selection of adaptable combustion systems

CONTROLS

Full range / choice of controls

FUEL SELECTION

Flexibility of choice in solid residue burning

Eco Chart

EMISSIONS

Carbon reduction

SOURCING

Local sourcing of material