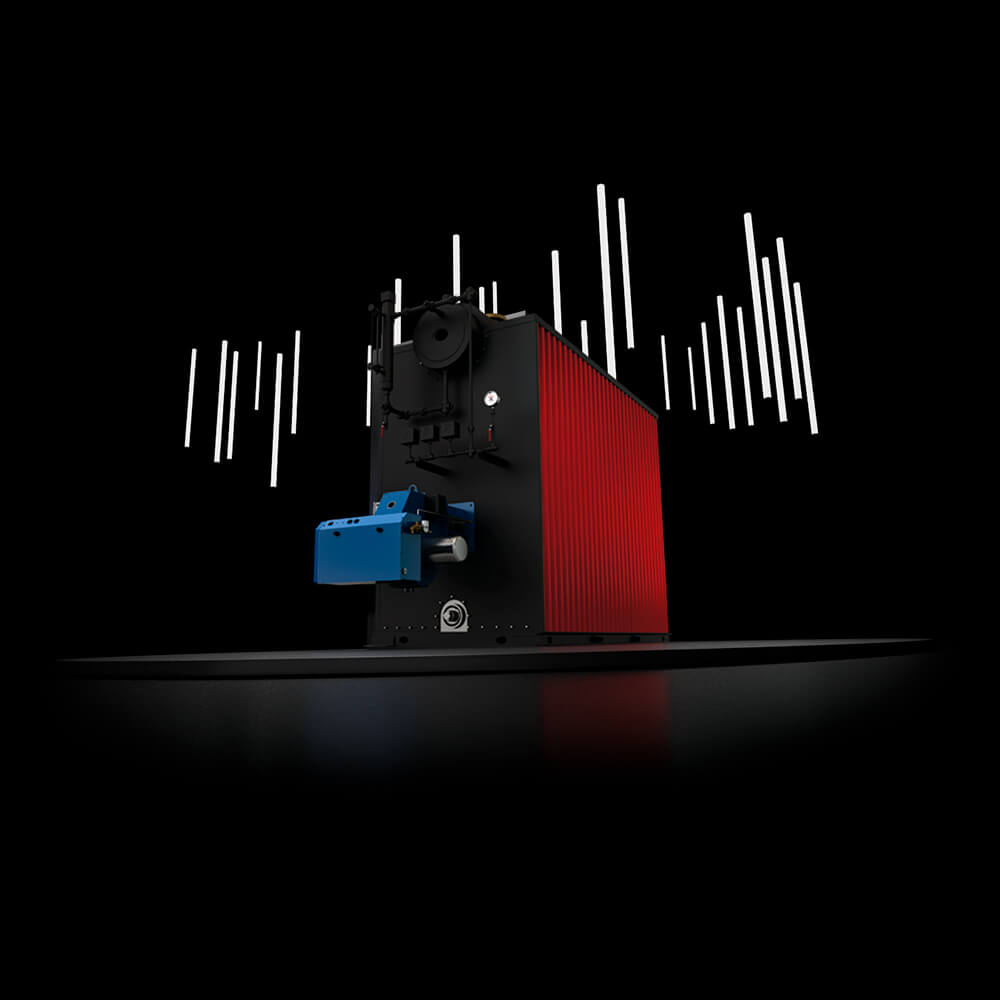

Flextube Boilers

When you look at the inner workings of a flextube boiler, with its intricate serpentine design made up of a series of water tubes, it’s tempting to think that you’re not dealing with the most optimal energy system.

This couldn’t be further from the facts.

“At Simoneau, we’ve raised the bar when it comes to flextube boiler design and engineering with the MaverickTM: the world’s most flexible boiler made for multiple applications and fuel solutions.”

Get flexible; stack the odds in your favour

Whether you’re looking to generate low or high temperature water or thermal fluids, either to access low- or high-pressure steam, the MaverickTM flextube boiler is the way to go. This multipurpose and compact boiler comes with an integrated economizer which makes it one of the most efficient of its kind. In fact, adding a second economizer to its system increases its fuel efficiency to 95%.

Maximized flexibility also translates to maximize total cost of ownership (TCO) with the MaverickTM. Its superheater component is designed to reheat generated steam, and whatever doesn’t turn into steam is funnelled into its large downcomers. Through that process, optimal atmospheric temperatures are continuously maintained within the boiler. In short, nothing is wasted, and you significantly save on fuel costs.

And what about its compact size? Yes, it has a lower footprint compared to other industrial packaged boilers. But, more importantly, you’ll find inside a modern conception made up of optimally bent and staggered tubes designed to ensure maximum heat transfer and help prevent thermal shocks. Plus, thanks to its reduced size, little space is required for tube withdrawal. Another win for your TCO!

It’s what’s inside that counts

Won’t water deposits accumulate in every nook and cranny of the boiler’s bent tubes? Is the heat transfer truly making its way at the needed speed? It must be a pain to ensure its maintenance, right? But it’s so small…How on earth can it produce the energy levels that I need to keep my business running?

“The short answer: With the MaverickTM flextube boiler, which was engineered for industrial purposes, you’re actually getting a higher steam quality at a quicker pace while having all the flexibility you need to operate. It’s the boiler that allows you to remain industrially competitive in an ever-changing world.”

Designed and conceived for today’s industries that juggle with modular energy production and batch processing, the MaverickTM is the result of more than 15 years of boiler innovation and technology. It allows businesses to remain highly adaptable and agile when faced with intensive and constant industry transformations and energy demands. In a word, it’s the boiler that helps businesses to stay relevant and ahead of the curve.

Don’t get the facts all twisted

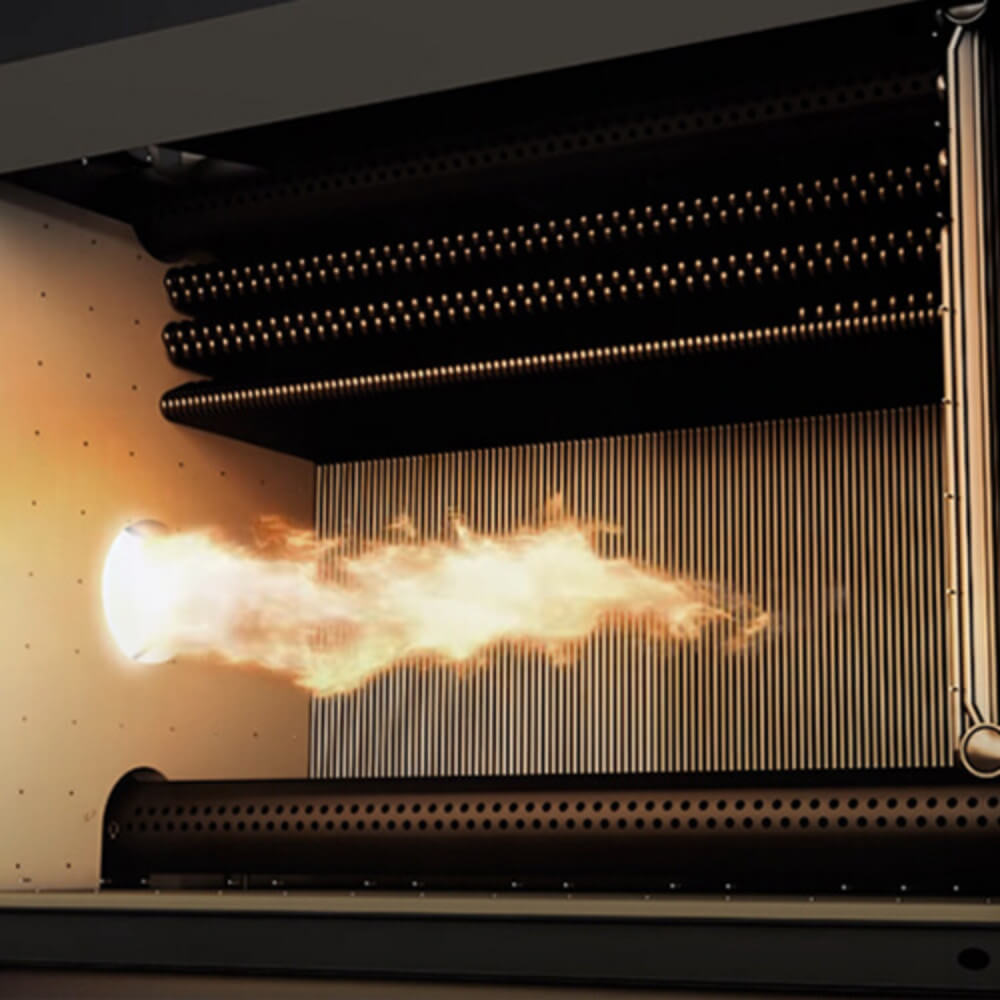

In order to maximize on engineering, a flextube boiler uses a tangent tube configuration that ensures impeccable water flow. The tubes, which have no deformities, are actually stronger and thicker when compared to other systems/models. It’s all about maintaining quality at all times; steam purity at 99.5%, that is. In fact, with a longer and uncurved tube, you run more risks of actually losing heat.

A bent, staggered tube configuration allows for a better exposition to the flame within the boiler, doubling in turn the circulation passes at each round point which helps to secure optimal heat.

Truly, there’s a quality in those bends that is undeniable.

Flexibility and efficiency at work

Custom made for all applications and patented in Canada and the US, you’ll find the MaverickTM flextube boiler in various industries, including food processing and distilleries, and for district heating purposes. It’s also great for businesses located in Ontario looking for low-water solutions.

“Extremely fast, natural internal circulation, resulting in maximum heat transfer and operating efficiency; that’s what you can expect from a flextube boiler.”